The healthcare industry has experienced a significant transformation in recent years, driven by advancements in technology. One such innovation that has gained traction is the integration of 3D printing into computer numerical control (CNC) machines, revolutionizing the way medical equipment and devices are produced.

Overview of 3D Printing Technology in CNC Machines

Understanding 3D Printing in CNC Machines

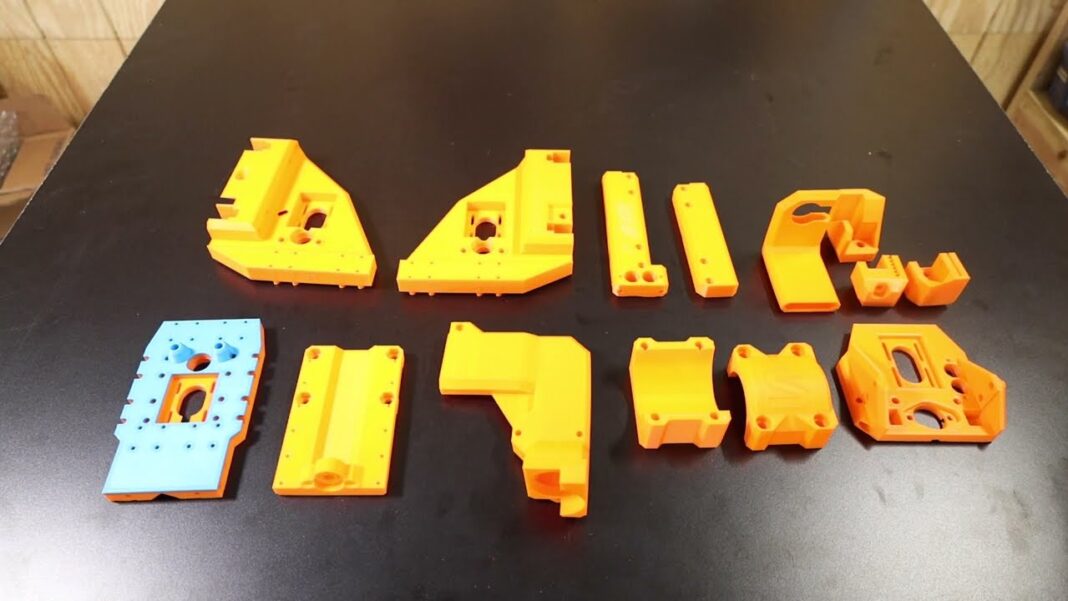

3D printing, also known as additive manufacturing, is a process that creates three-dimensional objects by building them up layer by layer. When combined with CNC technology, which uses computer-controlled machinery to precisely cut and shape materials, the result is a powerful tool for the healthcare industry.

Benefits of Integrating 3D Printing with CNC Machines

The integration of 3D printing and CNC machines offers several advantages, including:

- Customization: The ability to create personalized and tailored medical devices and equipment to meet the unique needs of patients.

- Precision: CNC machines provide unparalleled accuracy and repeatability, ensuring the production of high-quality medical components.

- Faster Prototyping: 3D printing allows for rapid prototyping, enabling faster development and testing of new medical products.

- Cost Efficiency: The combination of 3D printing and CNC technology can lead to significant cost savings, especially in small-batch production.

Advancements in Materials and Techniques

The 3D printing materials used in medical CNC machines have evolved to include a wide range of biocompatible and durable materials, such as medical-grade plastics, metals, and ceramics. Additionally, various 3D printing techniques, including fused deposition modeling (FDM), stereolithography (SLA), and selective laser sintering (SLS), have been adapted for medical applications.

Advantages of 3D Printed CNC Machines in Healthcare

Enhanced Personalization and Customization

One of the primary advantages of 3D printed CNC machines in healthcare is their ability to create highly customized medical devices and equipment. By leveraging 3D scanning and modeling technologies, healthcare professionals can design and produce patient-specific prosthetics, orthotics, implants, and surgical guides that perfectly fit the individual’s unique anatomy.

Personalized Prosthetics and Orthotics

3D printed CNC machines have revolutionized the production of prosthetic limbs and orthotic devices. Patients can now receive custom-fitted prosthetics and orthotics that are more comfortable, functional, and aesthetically pleasing, improving their quality of life.

Custom Implants and Surgical Guides

The precision of 3D printed CNC machines has also enabled the creation of personalized surgical implants and guides. These custom-made devices can be designed to fit the patient’s anatomy precisely, reducing the risk of complications and improving surgical outcomes.

Improved Medical Device Manufacturing

3D printed CNC machines have also had a significant impact on the manufacturing of medical devices, from small components to larger medical equipment.

Efficient Production of Complex Geometries

The additive manufacturing capabilities of 3D printing allow for the creation of intricate and complex geometries that would be challenging or even impossible to produce using traditional manufacturing methods. This enables the production of sophisticated medical devices with improved functionality and performance.

Rapid Prototyping and Iterative Design

The rapid prototyping capabilities of 3D printing, combined with the precision of CNC machines, allow for faster iteration and testing of new medical device designs. This accelerates the product development process, enabling healthcare companies to bring innovative solutions to market more quickly.

Enhanced Accessibility and Affordability

The integration of 3D printing and CNC technology in the healthcare industry has also contributed to increased accessibility and affordability of medical devices and equipment.

Decentralized Production

3D printed CNC machines can be placed in local healthcare facilities, enabling on-demand production of medical devices and reducing the need for centralized manufacturing and long-distance transportation. This decentralized approach can improve access to essential medical products, especially in remote or underserved areas.

Cost Savings

The cost-effective nature of 3D printing and CNC technology can translate into significant savings for healthcare providers and patients. By reducing the need for traditional mass production and inventory management, 3D printed CNC machines can lower the overall costs of medical device and equipment manufacturing.

Case Studies: Successful Implementation in Medical Device Manufacturing

Personalized Prosthetic Limbs

One notable case study is the use of 3D printed CNC machines to produce customized prosthetic limbs. A leading prosthetics manufacturer has leveraged this technology to create personalized prosthetic legs and arms that are tailored to each patient’s unique anatomy and lifestyle requirements. The result has been increased comfort, improved functionality, and enhanced patient satisfaction.

Customized Orthopedic Implants

Another successful case study involves the use of 3D printed CNC machines in the production of personalized orthopedic implants. A major medical device company has developed a process to design and manufacture custom-fit hip, knee, and ankle implants using patient-specific data obtained from 3D scans. This has led to better surgical outcomes, faster recovery times, and reduced rates of implant rejection or complications.

Surgical Guides for Complex Procedures

In the field of surgical instrumentation, 3D printed CNC machines have enabled the creation of highly accurate and patient-specific surgical guides. A renowned hospital has adopted this technology to produce customized guides for complex procedures, such as spinal surgeries and joint replacements. These guides have improved surgical precision, reduced operating times, and enhanced patient safety.

Customization and Precision in Medical Equipment Production

Adapting to Individual Patient Needs

The ability to produce customized medical equipment and devices using 3D printed CNC machines is a game-changer in the healthcare industry. By leveraging advanced scanning and modeling technologies, healthcare professionals can now design and manufacture products that precisely fit the unique anatomy and needs of each patient.

Personalized Prosthetics and Orthotics

One of the most significant areas of customization is in the production of prosthetic limbs and orthotic devices. 3D printed CNC machines allow for the creation of highly individualized prosthetics and orthotics that not only enhance functionality but also improve the user’s comfort and self-confidence.

Customized Surgical Implants

The precision of 3D printed CNC machines has also enabled the development of personalized surgical implants, such as hip, knee, and spinal implants. These custom-fit devices can be designed to seamlessly integrate with the patient’s anatomy, reducing the risk of complications and improving long-term outcomes.

Improved Accuracy and Repeatability

In addition to customization, 3D printed CNC machines offer unparalleled accuracy and repeatability in the production of medical equipment and devices. The computer-controlled nature of these machines ensures consistent and precise manufacturing, which is crucial in the healthcare industry.

Tight Tolerances and Consistent Quality

The tight tolerances and consistent quality achieved through 3D printed CNC machines are particularly important for the production of medical components, such as surgical instruments, prosthetic limbs, and orthopedic implants. This level of precision helps to ensure the safety and effectiveness of these products.

Reduced Defects and Waste

The accuracy of 3D printed CNC machines also leads to a reduction in product defects and waste, which can have significant cost and environmental implications for healthcare organizations.

Cost Efficiency and Time Savings in Healthcare Manufacturing

Reduced Production Costs

The integration of 3D printing and CNC technology in the healthcare industry has the potential to significantly reduce the overall costs of medical device and equipment manufacturing.

Elimination of Tooling and Molds

Traditional manufacturing methods often require the creation of expensive molds and tooling, which can add significant upfront costs to the production process. 3D printed CNC machines, on the other hand, eliminate the need for these costly tools, resulting in significant cost savings.

Decreased Inventory and Storage Requirements

The on-demand production capabilities of 3D printed CNC machines can reduce the need for large inventories of medical products, as devices can be manufactured as needed. This can lead to decreased storage and inventory management costs for healthcare providers.

Faster Time-to-Market

The rapid prototyping and iterative design capabilities of 3D printed CNC machines can significantly shorten the product development timeline for medical devices and equipment.

Accelerated Design and Testing

The ability to quickly produce and test new designs using 3D printed CNC machines allows healthcare companies to iterate on product concepts and bring innovative solutions to the market faster.

Reduced Lead Times for Customized Products

The customization capabilities of 3D printed CNC machines also enable faster delivery of personalized medical devices, such as prosthetics and orthotic devices, directly to patients, reducing wait times and improving access to essential healthcare products.

Environmental Impact: Sustainable Manufacturing Practices

Reduced Waste and Resource Consumption

The additive manufacturing nature of 3D printing, combined with the precision of CNC technology, can lead to more sustainable manufacturing practices in the healthcare industry.

Minimized Material Waste

Traditional manufacturing methods often result in significant material waste, as excess material is removed during the production process. 3D printed CNC machines, on the other hand, only use the necessary amount of material, reducing waste and improving resource efficiency.

Efficient Use of Energy and Water

The automated and computer-controlled nature of 3D printed CNC machines can also lead to more efficient use of energy and water resources during the manufacturing process, contributing to a smaller environmental footprint.

Increased Product Lifespan and Recyclability

The customization and precision capabilities of 3D printed CNC machines can also extend the lifespan of medical devices and equipment, reducing the need for frequent replacements.

Durable and Long-Lasting Products

The ability to produce high-quality, personalized medical devices and equipment using 3D printed CNC machines can result in products that are more durable and have a longer useful life, minimizing the demand for replacements and waste.

Improved Recyclability and Remanufacturing

Many of the materials used in 3D printed CNC machines, such as medical-grade plastics and metals, can be easily recycled or remanufactured, further contributing to the sustainable lifecycle of healthcare products.

Future Trends and Potential Developments in Medical CNC 3D Printing

Advancements in Materials and Printing Techniques

As the healthcare industry continues to embrace the integration of 3D printing and CNC technology, we can expect to see ongoing advancements in the materials and printing techniques used in medical applications.

Biocompatible and Biodegradable Materials

The development of new biocompatible and biodegradable materials, such as specialized polymers and ceramics, will enable the creation of even more advanced medical devices and implants that can be seamlessly integrated into the human body.

Improved Printing Resolutions and Speed

Continuous improvements in 3D printing resolution and speed will further enhance the precision and efficiency of medical CNC manufacturing, allowing for the production of increasingly complex and intricate healthcare products.

Increased Collaboration and Integration

The successful implementation of 3D printed CNC machines in the healthcare industry will likely lead to increased collaboration between various stakeholders, including healthcare providers, medical device manufacturers, and technology companies.

Integrated Design and Production Workflows

The integration of 3D scanning, computer-aided design (CAD), and CNC manufacturing will result in more streamlined and efficient workflows, enabling healthcare professionals to design, prototype, and produce personalized medical devices and equipment with greater ease.

Partnerships and Knowledge Sharing

Increased collaboration and knowledge sharing between healthcare organizations, medical device companies, and 3D printing/CNC technology providers will drive the continued development and adoption of these innovative manufacturing solutions in the medical field.

Expansion into New Applications

As the capabilities of 3D printed CNC machines evolve, we can expect to see the technology expand into new and diverse areas of healthcare.

Tissue Engineering and Organ Printing

The integration of 3D printing and CNC technology has the potential to revolutionize the field of tissue engineering, enabling the production of custom-made tissue grafts and even the bioprinting of complex organs.

Personalized Pharmaceutical Manufacturing

The precision and customization capabilities of 3D printed CNC machines could also be applied to the production of personalized pharmaceutical products, tailored to the specific needs and characteristics of individual patients.

Challenges and Solutions in Adopting 3D Printed CNC Machines in Health Industry

Regulatory Compliance and Certification

One of the key challenges in the adoption of 3D printed CNC machines in the healthcare industry is the need to comply with strict regulatory requirements and obtain the necessary certifications for medical devices and equipment.

Navigating Regulatory Frameworks

Healthcare organizations and medical device manufacturers must navigate complex regulatory frameworks, such as those established by the Food and Drug Administration (FDA) and other governing bodies, to ensure the safety and efficacy of 3D printed medical products.

Establishing Quality Control Protocols

Robust quality control protocols and validation processes must be developed to demonstrate the consistency and reliability of 3D printed CNC machines in the production of medical devices and equipment.

Data Management and Cybersecurity

As 3D printing and CNC technology become more integrated into the healthcare industry, the management and security of sensitive patient and product data become critical considerations.

Secure Data Storage and Transmission

Ensuring the secure storage and transmission of patient-specific data, such as 3D scans and design files, is essential to protect patient privacy and maintain the integrity of the manufacturing process.

Cybersecurity Measures

Implementing robust cybersecurity measures, including access controls, encryption, and network security, is crucial to safeguard against potential cyber threats and data breaches in the healthcare supply chain.

Workforce Upskilling and Training

The successful adoption of 3D printed CNC machines in the healthcare industry also requires the development of a skilled workforce capable of operating and maintaining these advanced manufacturing technologies.

Ongoing Education and Training Programs

Healthcare organizations and medical device manufacturers must invest in comprehensive training programs to equip their employees with the necessary skills and knowledge to effectively utilize 3D printed CNC machines in their production processes.

Collaboration with Educational Institutions

Partnerships with educational institutions, such as universities and vocational schools, can help to develop specialized curricula and training programs to prepare the next generation of professionals for the evolving landscape of medical manufacturing.

Conclusion

The integration of 3D printing and CNC technology in the healthcare industry has revolutionized the way medical devices and equipment are designed, produced, and delivered. This innovative approach offers numerous advantages, including enhanced personalization and customization, improved medical device manufacturing, increased accessibility and affordability, and more sustainable manufacturing practices.

Through case studies and a detailed analysis of the various benefits, this article has highlighted the transformative impact of 3D printed CNC machines on the healthcare industry. From personalized prosthetics and customized implants to the production of complex surgical guides, these advanced manufacturing solutions are redefining the way medical products are developed and brought to market.

As the technology continues to evolve, with advancements in materials, printing techniques, and industry collaboration, the potential for 3D printed CNC machines to further revolutionize the healthcare sector is immense. However, addressing regulatory compliance, data management, and workforce training challenges will be crucial to ensure the successful and widespread adoption of this innovative technology.

Overall, the integration of 3D printed CNC machines in the healthcare industry represents a significant step forward in the pursuit of personalized, precise, and sustainable medical manufacturing, ultimately leading to improved patient outcomes and a more efficient and resilient healthcare system.